If you have ever worked in a noisy environment, you’ll know the detrimental effect it can have on your hearing and subsequently your health and wellbeing.

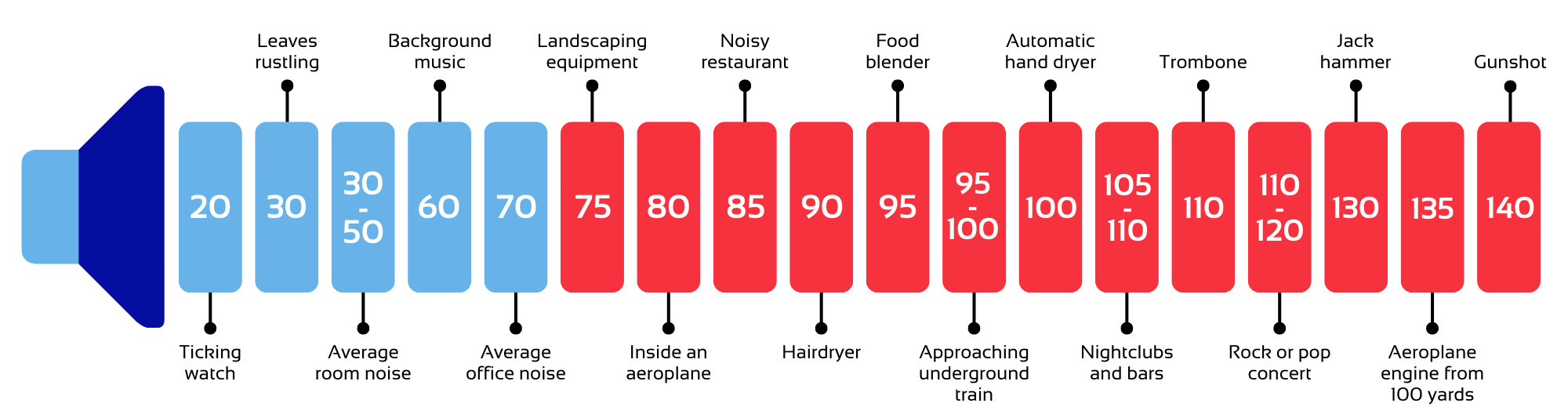

There are two ways to inflict damage on your hearing: one is to experience a sudden loud noise over 120 dB (decibels) and the other is a prolonged exposure to noise over 70 dB.

To give you an idea of what this might represent, an ordinary conversation would usually measure around 60 dB while the acceptable engine noise of a car has been gradually reduced and now must meet the 2016 standard of 72 dB maximum for new vehicles. Travelling by passenger aircraft can expose you to around 80-85 dB during a flight, depending on the insulation and model type. However, the levels at rock concert can often reach an eye-watering and ear-damaging 110-120 dB.

Hearing damage is a serious and lifelong issue for many, with around a tenth of the adult population in the UK living with tinnitus and one in six being affected by other kinds of hearing loss.

While ear protectors and other noise-limiting tools can help protect workers against the operating noise of an air compressor, we are often asked if it’s possible to buy a quiet or silent air compressor.

There are no completely silent air compressors, however, the noise emitted can vary widely. The average is currently 85 decibels but some models run as high as 92 db and there are models that operate as low as 40-55 dB. So clearly there is such a thing as a quiet air compressor when compared with the noisiest models on the market.

The UK Control of Noise at Work Regulations 2005 requires employers to measure the risk faced by workers, offer training and provide information about the danger of high levels of noise if they are exposed to 80 dB or more. If average exposure is as high as 85 dB, hearing protection and zones must be provided, and no worker should be exposed to levels over 87 dB.

This requirement for compliance with noise regulations in the UK has informed research and development into ways to reduce the noise produced by compressed air systems.

Situated at the forefront of innovative technological advances, Atlas Copco has made noise reduction an important feature of its newest models.

Of the three main types of air compressor – piston, rotary screw and scroll – the quietest is the scroll compressor. Of the others, single piston compressors are usually noisier than dual piston models and rotary screw compressors are quieter than both.

The reason for the difference in noise output can be explained by reasons such as how much friction there is in the moving parts. For example, in rotary screw compressors, the air element helical screws don’t come into contact with each other so there is less friction and vibration.

Another factor is whether the compressor is powered by electricity or by gas where a noisier engine is required.

The closer your workers are to the air compressor, the more noise they will be exposed to, so you could start by looking at ways of isolating the compressor in a separate soundproofed space. There are also measures you can take in the room or around the area where the air compressor is located, to reduce the amount of noise reaching workers.

However, as this isn’t always possible, the best option is to invest in an air compressor that has specific features to reduce its operational noise.

The Atlas Copco range of quiet compressors includes the G and GA models, SF and SF+ models and the VSD+ range.

Measures taken to reduce noise include dampening the sound by encasing the compressor in a full or partial enclosure and quieter or silent fans.

The GA VSD+ state-of-the-art models have a range of features that make them quieter, including a patented optimised silent fan and a close-coupled drive train, which combines a high-efficiency motor and asymmetric compression element. Designed in-house the motor has advanced cooling abilities and is so quiet that users have sometimes wondered if the compressor is switched on!

Another benefit of these super-quiet compressors is that they are extremely energy efficient – a must in this era of high energy costs.