Every industry has its cowboys – and they don’t usually turn up in a Stetson for easy identification. When it comes to air compressor engineers, the best way to distinguish the good from the bad and the ugly is to ask about their training and qualifications.

Here at PPS we are committed to providing the best possible service, the moment you meet a member of our sales team to the delivery and installation of your air compressor, vacuum pump, pneumatics, pipework and ducting.

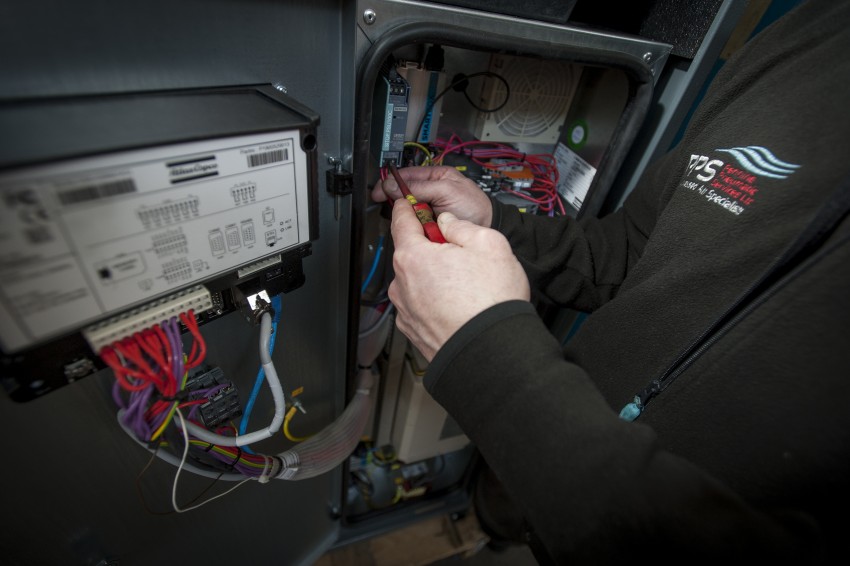

But it doesn’t stop there. Whether you have taken out an air compressor service contract with us for peace of mind or are contacting us for an emergency repair after a breakdown, our goal is to provide you with a professional service from well-trained, highly qualified engineers.

Why should you ask for a qualified compressed air engineer?

The simple answer is, because they know what they are doing. At PPS, we service all brands and ensure that the engineers sent out to your site are experienced enough to deal with any eventualities.

A qualified engineer will ensure that:

You probably won’t be surprised to hear that many large companies will not allow an engineer on site until they have shown proof of their accreditation.

Quality training from the start

While many PPS staff have years of experience under their belt, we’re also conscious of the need to train up the next generation of engineers.

When we take on new apprentices, we ensure that they are supported through their training programmes, which generally lead to a Level 3 qualification in Mechanical and Electrical Engineering. This includes allocating time for classroom and online study as well as on-the-job training, such as accompanying qualified engineers out on a job or helping to repair machinery in the workshop.

As one of our current apprentices says: “At present I’m shadowing one of the electrical engineers at PPS. They like apprentices to be hands on, which is a better way to learn things, in my opinion. If I’d stood back and watched, I wouldn’t have learned as much.”

Experienced staff

Our experienced engineers also come up through the apprenticeship system, whether at night school or day release to college, but may have followed different routes into the compressed air industry.

Some have a background in factory maintenance, where they have seen first hand the importance of a reliable supply of compressed air to keep production going. Others have worked as vacuum engineers in sectors such as food and drink, or in the electrical industry.

One thing that they all have in common is their extensive industry knowledge, developed over many years of working in the compressed air or related industries and from going through regular training programmes.

As well as new apprentices and newly qualified engineers, we have members of staff who have been with the company for 25 years.

In-house training

We now employ a full-time Technical Trainer, who works with both customers and staff. Having a full understanding of new products released by our suppliers helps our engineers to install, maintain and repair machinery, ensuring that production at our customer’s premises runs as smoothly and efficiently as possible.

How qualified is your compressed air engineer – What accreditation do PPS engineers hold?

Safety Passport – All of our engineers are sent on a two-day training course at the end of which they receive a Safety Passport accredited by the Engineering Construction Industry Training Board (ECITB).

F-Gas – We also have specialist engineers who hold F-Gas accreditation for working on refrigerant dryers. Without this qualification, an engineer is not allowed to work on a dryer or break into a refrigerant system. Our company is on the online F-Gas Register, which is regulated by the Environment Agency appointed by the Department for the Environment, Food and Rural Affairs (DEFRA).

Safety Pass Alliance – Engineers who work on certain sites, for example major manufacturers of food and drink, will need additional accreditation through the Safety Pass Alliance. At PPS we work with several multi-national food producers and ensure that we only send qualified staff to work on their machinery.

Manual handling – we also offer training in manual handling to ensure that our engineers can attach chains, lift equipment and move heavy items safely.

Driving – any employee who operates a fork lift truck will receive the appropriate training.

In many cases, accreditation will last for three to five years. At the end of this time, our engineers will be required to take any necessary refresher courses.

How do air compressor engineers receive their training?

Our engineers are trained both in house and by the suppliers of the equipment they install, repair and maintain.

As a leading authorised Atlas Copco distributor and a supplier of a range of brands including AIRnet, Camozzi and Parker, we make sure that our engineers are kept informed about new products and receive frequent training on accredited courses with the manufacturer.

We also use a local organisation, Kirkdale Industrial Training Services Ltd (KITS), to deliver some of our training, such as the Safety Passport.

Conclusion

Trusting to chance is a risky strategy when it comes to inviting people into your business to work on expensive equipment. Working with PPS, you can be sure that we will send you qualified engineers with the experience to do the job as quickly and as efficiently as possible.