Atlas Copco GA FLX Range: a brand new compressor technology

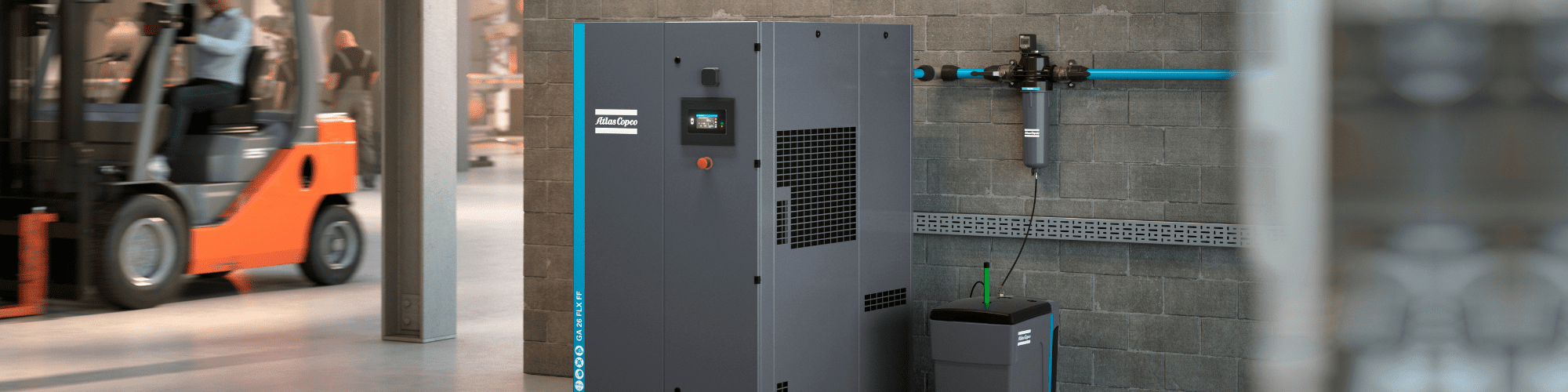

![]() The GA FLX range from Atlas Copco introduces a completely new compressor to the market – a dual-speed rotary screw compressor. The new technology will give you higher energy savings than any other fixed-speed machine.

The GA FLX range from Atlas Copco introduces a completely new compressor to the market – a dual-speed rotary screw compressor. The new technology will give you higher energy savings than any other fixed-speed machine.

This compressor is different to traditional fixed-speed air compressors. The GA FLX has the capability to adjust to a minimum motor speed during unloading and can initiate operation under pressure. This gives you significant, double-digit energy savings. The GA FLX ensures optimal flow at various pressure settings, providing a truly versatile performance.

Key features of the new range:

Double digit energy savings

- Reduced transient and unload energy losses.

- Up to 20% lower energy consumption (compared to GA fixed-speed models).

- FASR motor equals IE5 standards.

- Up to 80% energy savings with heat recovery options.

Premium performance

- Ability to start under pressure, saving on start-up time and energy use.

- No loss of air flow between pressure settings.

- Variety of options available so you can tailor the compressor to your needs.

Advanced connectivity

- State-of-the-art Elektronikon® Touch controller.

- SMARTLINK real-time, remote monitoring and optimization.

- OPC UA available for production system integration.

Compact footprint

- Very small footprint to ensure easy and flexible installation.

- 50% smaller than fixed-speed GA.

- Full feature version with fully integrated dryer and filters saves on floor space.

What is a dual-speed compressor?

Fixed-speed compressors operate at a constant motor speed of 100% to achieve maximum air flow. However, when air demand is lower than the compressor’s maximum capacity, a fixed speed consumes a significant amount of energy, leading to wastage. In contrast, a dual-speed compressor operates at two speeds – one for maximum capacity and another at a minimum speed to minimize energy consumption during unload periods. So, it proves to be more efficient than a fixed-speed compressor, as it reduces transient and blow-off losses.

50% energy savings available with the VSD upgrade option

The GA FLX gives customers the option to upgrade their dual-speed compressor to a variable-speed-drive compressor, with just a single touch. After 1000 working hours, the customer will receive a report on the energy savings available through VSD, and how quickly a return on investment would be achieved.

This option can allow customers to see an upgrade in energy savings from 20% to 50%.

View the full technical brochure for the GA FLX range:

Let our team save you money »