PPS: 01422 321 772

On this page we have pulled together everything we know about how to achieve air compressor energy savings, so you can be sure you are getting the best out of your compressed air system.

Recognised as the fourth utility, compressed air is a key industrial cost – and one that has a major impact on the environment. Over 10% of electricity supplied to industry is used to compress air.

Typically compressed air accounts for 12% of the total energy costs for industrial manufacturers – and may be as much as 40% in some cases. Do you know what % it is on your energy bill? (We cover this further down the page if you don’t).

An inefficient compressed air system wastes money but also contributes to your company’s carbon footprint.

Before we go on – if you are here for quick wins, we suggest you check out our top 5 energy saving tips. The other thing we want to get in right at the start is the importance of life cycle cost analysis, up to 80% of your outlay over the lifetime of your compressor is likely to be on energy costs, not initial investment or maintenance costs but energy. So, it’s crucial to fully understand and control your systems energy usage.

Before we go on – if you are here for quick wins, we suggest you check out our top 5 energy saving tips. The other thing we want to get in right at the start is the importance of life cycle cost analysis, up to 80% of your outlay over the lifetime of your compressor is likely to be on energy costs, not initial investment or maintenance costs but energy. So, it’s crucial to fully understand and control your systems energy usage.

Scroll down to read on or use these links to jump to a section…

The British Compressed Air Society (BCAS) has advised on reducing energy consumption from compressed air usage. It recognises that compressed air is essential for British business but also that it is energy hungry – and that running systems at peak efficiency makes a major difference to costs and environmental impact.

For example, BCAS has said that:

The Carbon Trust is another organisation that champions ways to reduce energy waste. It supports businesses, governments and other organisations across the globe to work towards ambitious plans for a sustainable low-carbon future.

The organisation has found that as much as 30% of the energy in a compressed air system is lost due to leaks – the equivalent of the entire output of a medium-sized power station. And that even more is wasted due to the misuse of compressed air and poor maintenance of systems.

Essential maintenance such as replacing the intake filter, cleaning compressor coolers, radiators and ventilation grilles, and removing redundant pipework can all help to run a greener factory. Other tips include installing an automatic pressure controller, and minimising pressure drops by taking readings and increasing pipework diameter where necessary.

Don’t guess it. Measure it and control it.

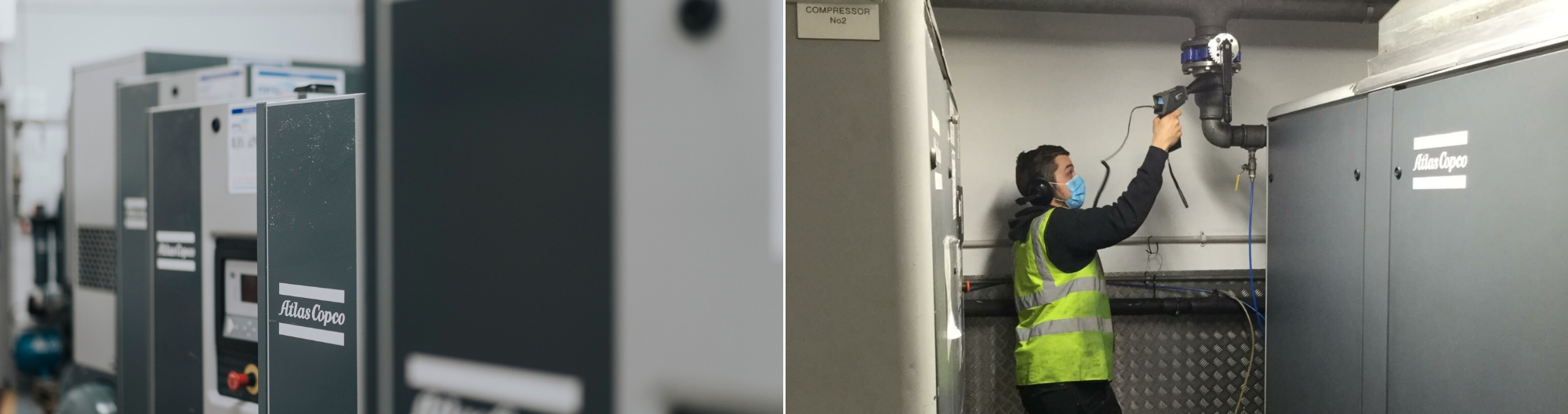

Compressed air energy audits help to give you real-life data so you can make accurate decisions. It does this by looking at your plant’s compressed air demand, pressure and cycle over a seven-day period. Is it going to tell you that you need a completely new system? It might, but not necessarily. It could show you that at times you are just feeding leaks in your pipework system. Or highlight that you need a better control system as staff aren’t stopping the compressor when the shift finishes. Whatever the audit results are, it puts you in a better position to improve the energy efficiency and productivity of your system. Like we said at the top of the page, this auditing exercise means you can see what % of your energy bill is made up by compressed air.

If you are looking for more regular insight than an annual or ad hoc energy audit, then have a nosey at our air compressor monitoring options. SMARTLINK from Atlas Copco gathers and analyses data from your compressed air system, so you can view it remotely. Specifically for energy, the energy licence includes insights into energy consumption, evolution and efficiency. It tracks how much energy you save and your CO2 reduction. Need to show compliance with ISO50001? Tick, this solution does that.

If you are looking for more regular insight than an annual or ad hoc energy audit, then have a nosey at our air compressor monitoring options. SMARTLINK from Atlas Copco gathers and analyses data from your compressed air system, so you can view it remotely. Specifically for energy, the energy licence includes insights into energy consumption, evolution and efficiency. It tracks how much energy you save and your CO2 reduction. Need to show compliance with ISO50001? Tick, this solution does that.

Correctly sized equipment makes your system more efficient, ok it sounds common sense when you read it like that, but we have seen it many times where old compressors are replaced with a new one that is the same kW rating. The best approach is to work out the pressure and flow required for your application. We talk about what size air compressor you need in greater depth here. In short:

We have genuinely visited a site where they had turned up the radio to drown out the sound of the air leaks. Yes, in this section we are talking about your compressed air pipework.

![]() A major source of wasted energy and unnecessary cost in most factories, air leaks have various causes; but one 3mm hole in your compressed air pipework could cost you between £500-£900 a year, depending on your compressed air system and the pressure it runs at. We’ll leave you to do the maths and multiply that across a whole site.

A major source of wasted energy and unnecessary cost in most factories, air leaks have various causes; but one 3mm hole in your compressed air pipework could cost you between £500-£900 a year, depending on your compressed air system and the pressure it runs at. We’ll leave you to do the maths and multiply that across a whole site.

Leaks aren’t the only thing affecting your pipework efficiency, but a leak detection survey gives you a quick result; here’s your problems, here’s your fixes, here’s your energy savings = result.

Other things to be aware of for energy efficient pipework include:

We look a lot further into pipework energy savings here and discuss a few case studies if you think this is an area where you can become more efficient.

According to BCAS only 10% of the electrical energy input to an air compressor is converted into compressed air energy. The other 90% is wasted as heat. Approximately 70% of energy is recoverable from oil-injected screw compressors – this comes from research done by Atlas Copco. Atlas Copco have also calculated that compressor heat recovery could save 1.99% of the total industrial electricity consumption in the UK. Wow, a vast untapped potential.

What many of our customers have been doing is simply having a variable control damper on their outlet ducting. They can discharge hot air externally during summer but then change this to a workshop or warehouse during the winter.

A tip from the Carbon Trust is that by placing a compressor in a warehouse it may provide enough heat to prevent product and packing materials (e.g. cardboard boxes) becoming damp.

![]() A more intricate system we installed for a customer in the automotive sector involved recovering the heat from the air compressor oil system so they could pre-heat the boilers and shorten their burn time. It also meant they no longer had to use their emersion heater during the summer months.

A more intricate system we installed for a customer in the automotive sector involved recovering the heat from the air compressor oil system so they could pre-heat the boilers and shorten their burn time. It also meant they no longer had to use their emersion heater during the summer months.

This white paper from Atlas Copco delves a lot deeper into this subject.

For most compressors, a reduction of 1 bar in pressure (14.5 psi) could lead to a 7% saving in electricity consumption.

For most compressors, a reduction of 1 bar in pressure (14.5 psi) could lead to a 7% saving in electricity consumption.

Some customers are used to thinking they have to run a system at a particular pressure, so it’s a surprise to them when we say they can reduce pressure without affecting production. Anyone can potentially benefit from lowering pressure, from engineering to manufacturing companies. It can save a lot of energy over the course of a year.

How low do you go?

A data log of your system will allow you to work this out. Using our software, we can simulate different outcomes depending on the level the pressure is set. This is usually incremental until we find the sweet spot. We won’t drop the pressure by extreme amounts as we don’t want to shut down the machinery by running it too low.

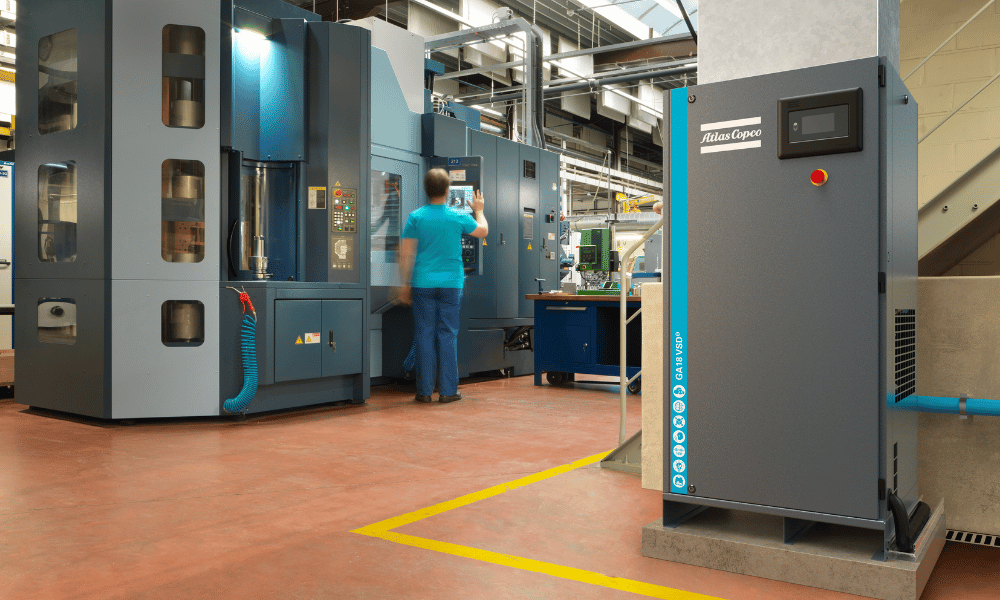

Many industrial applications have fluctuating air demand. Using a fixed speed compressor for this results in wasted energy. This is because fixed speed compressors run either “on load” where the motor is turning and producing air or “off load” where the motor is tuning and using energy, but no air is being produced. Fixed speed compressors run like this to prevent electrical stress within the compressor.

A variable speed drive air compressor can deliver up to 60% energy savings compared to a fixed speed compressor as it only produces compressed air when it is needed. This is why VSD compressors are the most energy efficient option.

Is your compressor left running when air is not needed?

Is your compressor left running when air is not needed?

A 30kW compressor can consume approximately 11kW of electricity when off load, so taking measures will save you energy – and money.

There are two possible ways to save energy if this is happening:

If a factory has multiple machines, without a central controller, you have to ‘cascade’ them. This means that you must keep the overall pressure artificially higher, as the last machine in the system must have pressure at a usable level for the process.

With a central controller, it will run the system on the smallest amount of pressure required, keeping the overall pressure at the smallest level possible and reducing energy costs.

There are a few different versions of controllers. With the more basic ones, you can set the order and the system will rotate the machines in sequence, regardless of size. The more advanced intelligent controllers will measure use and configure the sequence accordingly.

As stated by BCAS (British Compressed Air Society), compressor output will deteriorate by more than 10% without proper maintenance.

This takes into account things like:

The PPS Service team are able to advise and guide your site on the correct level of servicing needed to maintain efficiency and avoid downtime.

It really is a whole system approach for energy saving and optimum efficiency. From the plant room to point of use there are always steps you can take, no matter how small they may seem.

Tips to improve: