The PPS Energy team are your go-to experts if you want to save money and reduce the carbon footprint of your compressed air system. Whatever your industry, they can help you measure and control your energy usage, recommend changes and guide you through the options. Even small changes can lead to substantial savings.

Heading up the team is Jason Boyle, supported by Energy Audit Engineers Graham Patchett, Mark Harris and Jayant Magdum. Here you can get to know the team a bit better and find out how their varied backgrounds make them the perfect fit to help your manufacturing site work efficiently.

Jason’s background in electrical engineering, coupled with his almost 10 years’ experience at PPS, has made him the king of control in our compressed air team. Why is Jason passionate about control? Well…

Jason’s background in electrical engineering, coupled with his almost 10 years’ experience at PPS, has made him the king of control in our compressed air team. Why is Jason passionate about control? Well…

“If a factory has multiple machines, without a central controller, you have to “cascade” them. This means that you have to keep the overall pressure artificially higher, as the last machine in the system has to have pressure at a usable level for the process. With a central controller, it will run the system on the smallest amount of pressure required, keeping the overall pressure at the smallest level possible and reducing energy costs” says Jason.

Jason adds: “There are a few different versions of controllers. With the more basic ones, you can set the order and the system will rotate the machines in sequence, regardless of size. The more advanced intelligent controllers will measure usage and configure the sequence accordingly. For bigger customers with a large number of compressors, these are a cost-effective investment.

“Control isn’t always about investment in new kit, sometimes it’s about behavioural change onsite or making the most of data available to you through software like Smartlink. The majority of my time is spent helping customers understand what is available on site, to give the best control of the complete system and maximise efficiencies.”

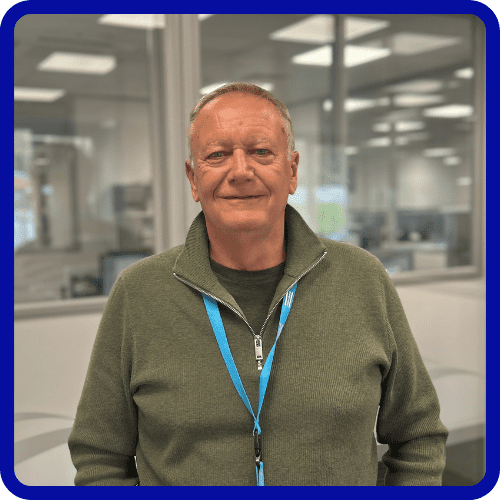

There’s not a lot Graham hasn’t seen in the compressed air world. He’s worked in plant rooms right across the UK since starting as an apprentice engineer in 1970. However, since 2006 he has been purely focused on energy auditing for PPS customers.

There’s not a lot Graham hasn’t seen in the compressed air world. He’s worked in plant rooms right across the UK since starting as an apprentice engineer in 1970. However, since 2006 he has been purely focused on energy auditing for PPS customers.

“When I joined PPS, as far as I know, we were the only compressor distributor that had a dedicated energy audit department. Within the last couple of years, the team has grown to four, which has enabled me to take a step back to allow the younger members to take the lead” says Graham.

“In terms of energy, PPS has always been a forward-thinking company and has invested heavily in additional equipment for data logging. This has meant we have been able to provide invaluable support for manufacturing sites over the years, never more so than during the recent energy price hike.”

Mark joined the PPS team in 2021 straight from university where he graduated with a Masters in Mechanical Engineering. It didn’t take Mark long to settle in to the team and build a reputation for being able to find the ‘sweet spot’ for the optimum pressure for customer systems.

Mark joined the PPS team in 2021 straight from university where he graduated with a Masters in Mechanical Engineering. It didn’t take Mark long to settle in to the team and build a reputation for being able to find the ‘sweet spot’ for the optimum pressure for customer systems.

Mark explains “I knew even before starting at university that I wanted to work in the energy sector in some way, so I focused mainly on thermodynamics and energy-oriented modules. This knowledge has been very useful at PPS, because I understood the fundamentals of compressed air, energy usage and flow, despite never having been exposed to the industry before.

“Two years in and I relish the challenge of helping customers reduce their carbon footprint. This is important to me in my personal life and my own decision-making focuses on having minimal impact on the planet. I think it is really important as a business that we work for the 3P’s of people, planet and profit, I’m proud that my role has an influence on this”.

The newest member of the PPS energy team, Jayant joined at the beginning of 2023. His previous role in compressed air had been for a respected firm in India where he was a Senior Sales Engineer. He has spent the last four years working with customers to specify the correct equipment for their application, while being mindful to deliver the most energy efficient option.

The newest member of the PPS energy team, Jayant joined at the beginning of 2023. His previous role in compressed air had been for a respected firm in India where he was a Senior Sales Engineer. He has spent the last four years working with customers to specify the correct equipment for their application, while being mindful to deliver the most energy efficient option.

“My role at PPS builds on my experience in India, but now the energy aspect of the compressed air system is my main role. I’m getting stuck into the data analysis and reporting side of the audits. The customer needs to be able to understand the energy used by their system, to then be able to manage and improve their energy usage.

“For me it is being able to provide a consultative approach and building relationships with the customer that is the most satisfying part of the job. Knowing you have understood their needs and delivered what they required to improve their business, makes all the data analysis worthwhile.”